-

6400 MALE JIC - MALE ORING CONNECTOR

Regular price From $0.99 USDRegular priceUnit price / per -

FEMALE JIC SWIVEL TO FEMALE PIPE CONNECTOR 6506

Regular price From $2.99 USDRegular priceUnit price / per -

MALE PIPE ELBOW 45 DEGREE 5501

Regular price From $2.99 USDRegular priceUnit price / per -

1405 Female Pipe - Female Pipe Swivel Union

Regular price From $2.99 USDRegular priceUnit price / per -

1404 Male Pipe - Female Pipe Swivel Union

Regular price From $1.99 USDRegular priceUnit price / per -

319 Jic Tube Sleeve

Regular price From $0.69 USDRegular priceUnit price / per -

318 Jic Tube Nut

Regular price From $0.99 USDRegular priceUnit price / per -

6502 Male Jic - Female Jic Swivel Elbow 45 Degree

Regular price From $12.99 USDRegular priceUnit price / per -

6815 Male Oring - Female Oring Elbow 90 Degree

Regular price From $5.99 USDRegular priceUnit price / per -

FF-6504 Male Jic - Female Flat Face Oring Connector

Regular price From $3.99 USDRegular priceUnit price / per -

FF-2501 Flat Face Male Oring - Male Pipe Elbow 90 Degree

Regular price From $2.99 USDRegular priceUnit price / per -

2705 Male Jic - Female Pipe Bulkhead

Regular price From $3.99 USDRegular priceUnit price / per -

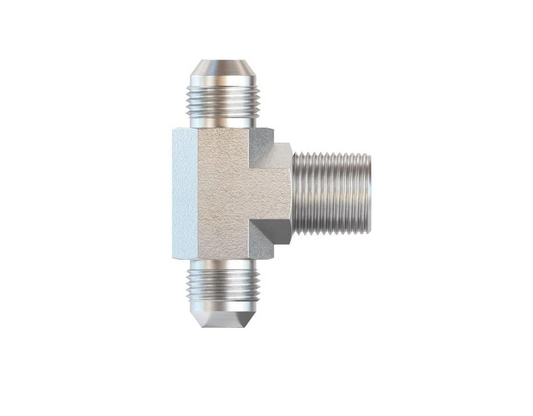

2601 Male Jic - Male Jic - Male Pipe Branch Tee

Regular price From $3.99 USDRegular priceUnit price / per -

FEMALE PIPE TO FEMALE PIPE SWIVEL ELBOW 90 DEGREE 1502

Regular price From $3.99 USDRegular priceUnit price / per -

306 Bulkhead Lock Nut

Regular price From $0.99 USDRegular priceUnit price / per -

FF-2500 Flat Face Male Oring - Flat Face Male Oring Elbow 90 Degree

Regular price From $3.99 USDRegular priceUnit price / per

Hydraulic Adapters and Fittings FAQs

Collapsible content

1. How do I properly measure hydraulic fittings?

Accurately measuring your hydraulic system components like hoses, pipes, and ports is crucial for selecting the correct adapter fittings. Use a caliper or measuring tape to determine metrics like hose inner and outer diameters, thread pitch and size, and port widths. Confirm all measurements twice for precision. Choosing wrong-sized hydraulic adapters can prevent secure connections or restrict critical fluid flows.

2. What’s the best place to buy hydraulic hose fittings and adapters?

We stock a wide range of hydraulic fittings and adapters like O-ring face seals, JIC connectors, NPT and metric thread types accommodating various hose and pipe sizes. Our corrosion-resistant stainless steel and brass hydraulic accessories meet demanding environments like marine hydraulic steering systems.

3. How do you properly seal hydraulic fittings and adapters?

Creating leak-free hydraulic connections requires properly sized and threaded adapters along with specialized hydraulic sealing compounds. Apply sealant to the adapter fitting’s threads then torque to the recommended specs using a calibrated torque wrench. This prevents overtightening or undertightening. Overtorqued fittings can crack housings and undertorqued causes leaks.

4. How are different hydraulic fittings identified?

Most hydraulic adapters feature embossed or stamped markings denoting thread pitch/type, size, flow direction, pressure rating, manufacturing codes and various metric measurements. At Hydraulic Warehouse we offer top performing fittings. Please check adapter fitting identification guides if markings seem unclear. You can also measure adapters using calipers to cross-reference marked thread dimensions.

5. Can hydraulic fittings be crimped at home without special tools?

That is not recommended - properly crimping hydraulic hoses relies on calibrated commercial crimpers and specialty dies matching specific fitting types and tubing sizes. Attempting to crimp using homegrown DIY methods like vise-grip pliers typically fails creating lasting, leak-prone connections. It is a better practice to work with factory-crimped hydraulic hoses or have a specialty hydraulic shop crimp custom hoses onsite with professional hydraulic crimping equipment.

6. What does JIC stand for in hydraulic fittings?

JIC is the common abbreviation for Joint Industry Council, an industry group that standardized 37° flared fittings widely used in hydraulic systems today. So JIC fittings utilize 37 degree flared tubing connections rather than pipe threads for reliable leak-free adapter connections under pressure.

7. Do you need to talk to an expert?

send us a message and we will be happy to assist you sales@hydraulicwarehouse.com